Introduction

This analysis focuses on comparing the technical performance of two types of block-bottom valve sacks used in the cement industry: one made from high-porosity paper and the other from laminated woven polypropylene (WPP). The evaluation was conducted across key markets, including Africa, the Middle East, Southeast Asia, Mexico, and Central America, where cement packaging plays a critical role in supply chain efficiency and product integrity.

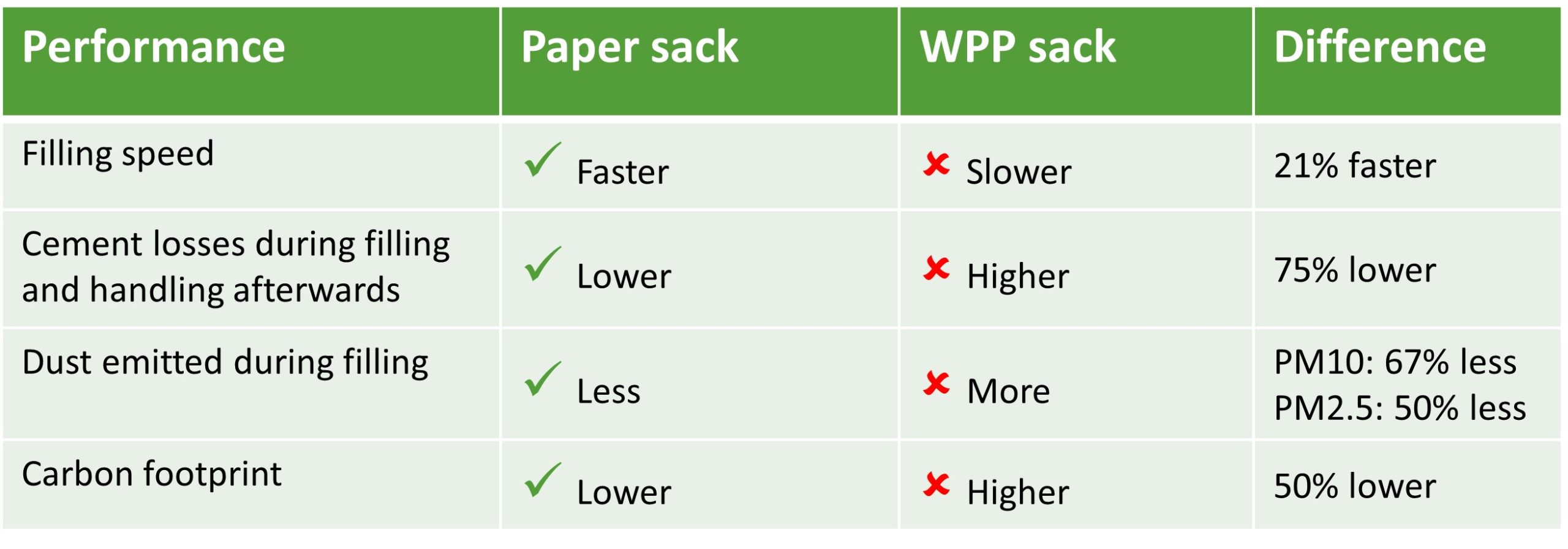

A range of technical differences between the two packaging materials were identified. These findings were further validated through laboratory testing and summarized in a project report.

To ensure a comprehensive and reliable assessment of the environmental impacts associated with each packaging solution, CEPI Eurokraft commissioned RISE (Research Institute of Sweden) to perform a comparative carbon footprint study. The study was subject to an independent third-party review, ensuring transparency and credibility in the results.

The results on this website refer only to these lab tests and to the conditions during the period of tests.

Result filling speed

The lab test demonstrated that the tested paper sacks are filled 21% faster with cement than the tested WPP sacks.

This makes paper sacks a highly cost-effective solution for cement brand owners. Additional advantages with paper sacks are no need of extra complex and costly air extraction systems to keep the high filling speed. To add to that, machine set-up and maintenance for paper sack filling machines are quicker, resulting in further lower operational costs.

Result cement losses

Cement losses from filling and handling afterwards (simulated by five drop tests from 90 cm height) were four times lower for paper sacks compared to WPP sacks.

The leakage in WPP sacks occured across their entire surface, leading to contamination along the supply chain. Such product loss also contributes to increased machine maintenance, longer downtimes for cleaning, and may cause health and safety risks for workers and the environment.

Result dust emitted

Dust in the form of PM10 and PM2.5, was measured during a filling lab study.

The emitted PM10 dust from paper sacks were 3 times less compared to the dust emitted from the WPP sacks.

The emitted PM2.5 dust from paper sacks were 2 times less compared to the dust emitted from the WPP sacks.

Carbon footprint study

A comparative Carbon Footprint study analyzed scenarios in four diverse countries: Ivory Coast (Africa), Saudi Arabia (Middle East), Mexico (Central America) and Indonesia (Southeast Asia), and followed a cradle-to-filler-out-gate approach.

The study demonstrates the total fossil-based global warming potential is approximately 50% lower for paper sacks compared to WPP sacks when packaging 50 kg of cement.

Conclusion

Paper sacks offer significant advantages over WPP sacks, including higher productivity, reduced environmental impact, faster filling times, and enhanced health and safety conditions. Their sustainability credentials and efficiency make them a superior packaging solution for cement.

More information

- Project report: “Comparative analysis of the technical properties and performances of paper sacks vs. woven polypropylene sacks“

- Carbon footprint report: “Comparative carbon footprint study: Paper sacks versus woven PP sacks in markets

outside Europe” - Fact sheets:

Speed of filling 50 kg cement in paper sacks and in WPP sacks

Cement losses in filling and handling from paper sacks and WPP sacks

Dust generated from filling operations in paper sacks and WPP sacks

Comparative Carbon Footprint study