The results in this fact sheet refer only to these lab tests and to the conditions during the period of tests.

Study overview

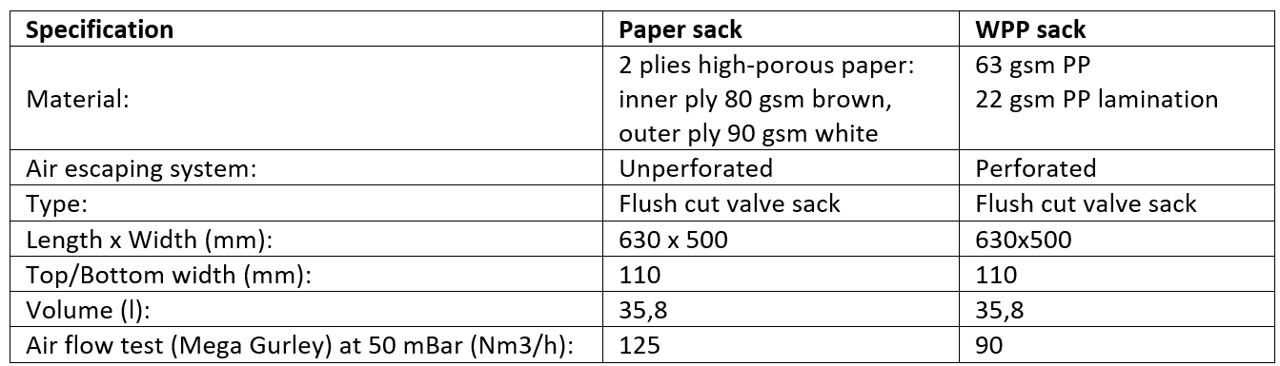

CEPI Eurokraft conducted a lab test to compare the speed of filling 50 kg cement into a paper sack versus a woven polypropylene (WPP) sack. The test was performed using a Haver & Boecker single spout impeller packer at the Billerud Packaging Development Center in Karlsborg, Sweden. The cement used was Portland cement from Heidelberg Materials in Slite, Sweden, with a density of 1,4 kg/l and a Blaine value of 4,132 cm²/g. Note, paper is suited also for higher cement Blaine values.

Packaging specifications

Test methodology

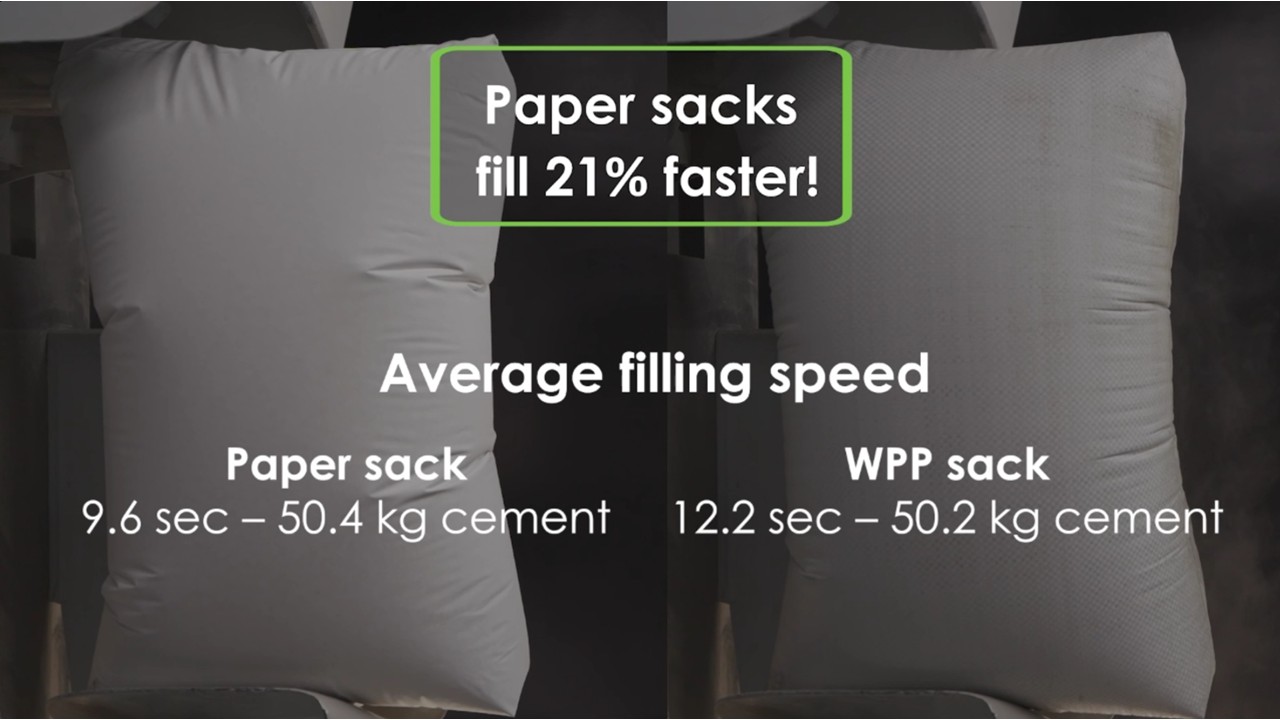

- Five samples per packaging type were filled with 50 kg cement.

- The first two samples for each packaging type were excluded based on machine supplier recommendations.

- An average value was calculated from the three remaining samples.

Key result

Paper sacks are filled 21% faster than WPP sacks with this machine setup.

Key findings

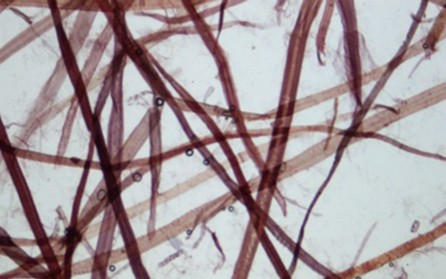

- The natural porosity of paper sacks allows for rapid and problem-free venting during filling.

- High-porous paper sacks eliminate the need for additional air extraction systems, reducing complexity and costs.

- Paper sack filling machines require less setup and maintenance, lowering operational expenses.

A special mechanical refining process of the long fibres results in a high bonding strength, which gives sack kraft paper its unique strength while at the same time keeping the porosity characteristics.

Conclusion

The study demonstrates that high-porosity paper sacks significantly improve cement filling speed, reducing operational costs and enhancing efficiency compared to WPP sacks.

A short video summarizes the study: