The results in this fact sheet refer only to these lab tests and to the conditions during the period of tests.

Study overview

CEPI Eurokraft conducted a lab test to investigate cement losses during the filling operation and subsequent handling of WPP sacks and paper sacks. The test was performed alongside the 50 kg cement filling speed study at the Billerud Packaging Development Center in Karlsborg, Sweden. The cement used was Portland cement from Heidelberg Materials in Slite, Sweden, with a density of 1.4 kg/l and a Blaine value of 4,132 cm²/g. Note, paper is suited also for higher cement Blaine values.

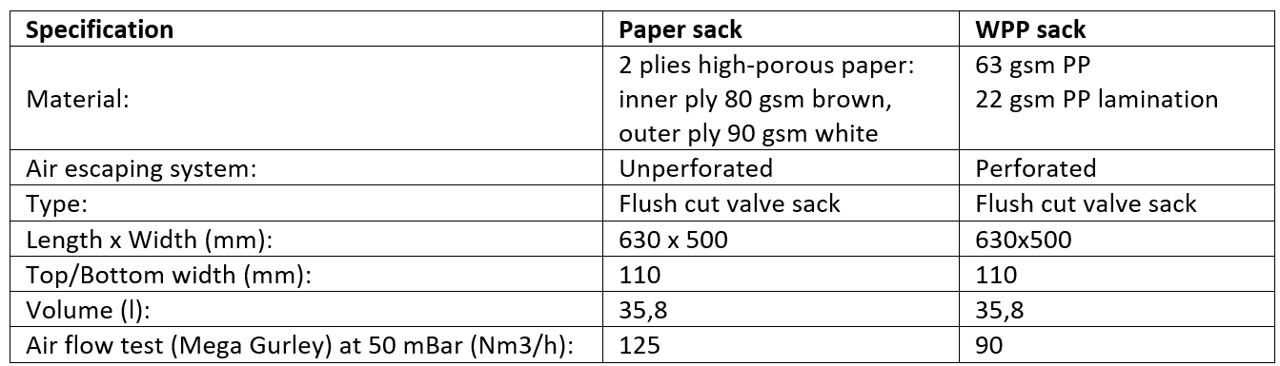

Packaging specifications

Test methodology

- Five samples per packaging type were filled with 50 kg cement.

- Cement losses during filling were measured by placing a white paper sheet under the filling equipment and weighing the collected cement particles.

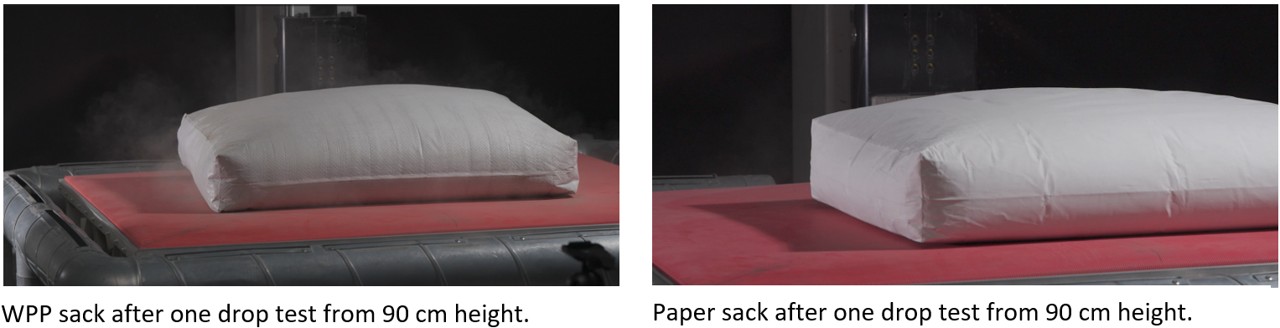

- To simulate real-life handling conditions after the filling process, each packaging went through five drop tests from 90 cm height, and comparing each sack weight before and after testing ensured accurate results.

Key results

- Cement losses during filling of WPP sacks are 4 times higher compared to the filling of paper sacks. However, the cement losses around the filling equipment are normally taken back to production.

- Cement losses in the handling of filled WPP sacks are 4 times higher compared to the handling of filled paper sacks. These losses are normally not taken back to production, since this happen in the distribution value chain.

- 172 ton cement per million ton of produced cement is getting lost via WPP sacks and 44 ton cement per million ton of produced cement is getting lost via paper sacks according to the study.

- By using paper sacks, a saving of 128 ton cement per million ton of produced cement would occur.

- Cement production is a fossil greenhouse gas (GHG) emission intensive industry, this saving can also be translated into a saving of 104 ton CO2e per million ton of produced cement.

Key findings

- Cement losses at the filling site increase maintenance costs, downtime for cleaning, and reduce equipment lifespan.

- Higher cement losses contribute to health and safety risks for employees.

- The WPP sack creates losses from both perforations and the woven surface, leading to inefficiencies.

- Reduced product loss improves overall efficiency and reduces environmental (fossil GHG emissions) impact.

Conclusion

The study demonstrates that paper sacks reduce cement losses compared to WPP sacks, resulting in cleaner operations, lower maintenance costs, and improved efficiency throughout the distribution supply chain.

A short video summarizes the study: