The results in this fact sheet refer only to these lab tests and to the conditions during the period of tests.

Study overview

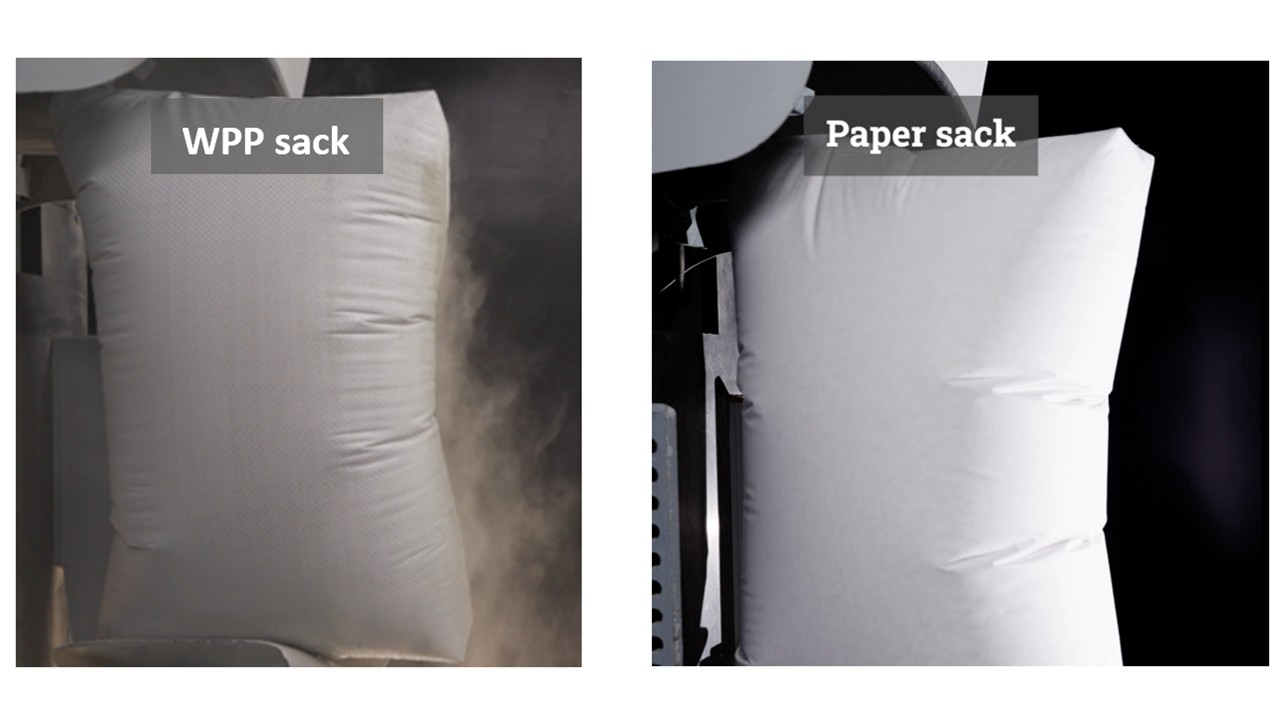

A dust study was conducted at the Mondi Frantschach Bag Application Center in Austria, aimed to measure and compare dust emissions during cement filling operations using high porous paper sacks and woven polypropylene (WPP) sacks. The Natro Tech-Air Packing Machine was used to fill the sacks with 50 kg cement, and dust measurements were taken by the Austrian Dust (Silicosis) Control Centre (ÖSBS) consultant.

Test methodology

- Dust measurements taken using two procedures:

- Direct measurement: With an aerosol spectrometer.

- Sampling process: Gravimetric analysis at an ÖSBS accredited laboratory.

- Sampling points:

- Left and right of the filling machine.

- 2 meters in front of the filling machine.

- Test protocol:

- 10 measurements per packaging type at each sampling point.

- Calculation of mean dust levels per sampling point and an overall mean value.

Key results

- Dust levels PM10 (Particulate Matter <10 µm):

- The emitted dust from WPP sacks was 3 times higher compared to the dust emitted from the paper sacks.

- Dust levels PM2.5 (Particulate Matter <2.5 µm):

- The emitted dust from WPP sacks was 2 times higher compared to the dust emitted from the paper sacks.

Key findings

- Porosity advantage of paper sacks: natural porosity allows air to escape without releasing cement particles/dust.

- Issue with WPP sacks: higher internal pressure during filling, leading to leakages not only from perforations but across the whole sack surface.

- Health implications: cement typically contains various chemicals and minerals, including lime, silica, calcium, aluminum, chromium, and iron. Health risks associated with these particles include:

- PM10: Can irritate the skin, eyes, nose, and throat.

- PM2.5: Can penetrate deep into the lungs.

- Potential health impacts: respiratory disorders, asthma, airway inflammation, and lung infections.

- If contact with the skin, a risk of developing skin problems, ranging from mild and brief to severe and chronic, can arise.

Conclusion

The study highlights the difference in dust emissions between paper sacks and WPP sacks during cement filling operations.

A short video summarizes the study: